Miner Fatigue Prevention

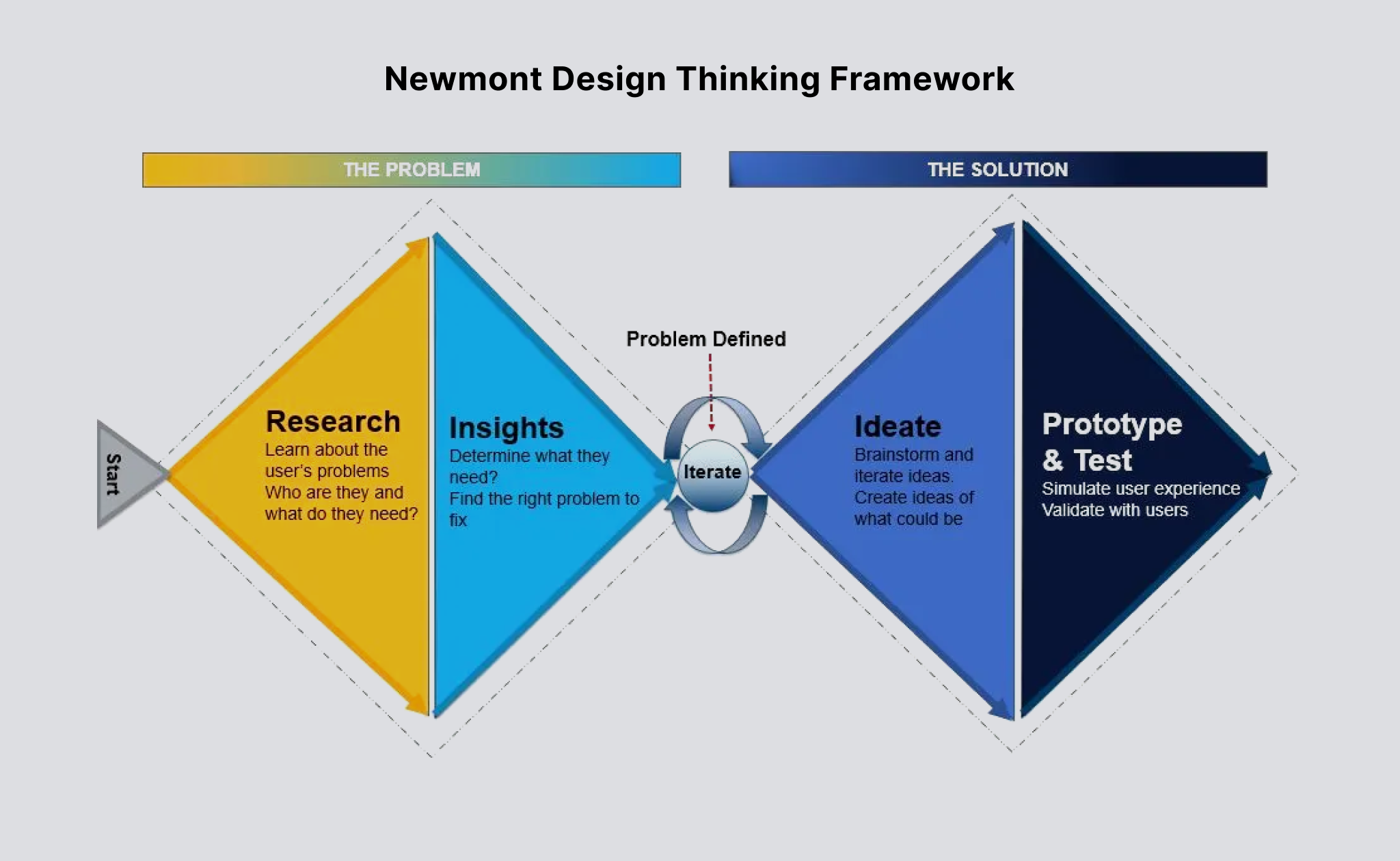

As a UX designer at Newcrest Mining, I joined the company's design thinking initiative aimed at solving operational challenges across different departments. The design team identified several problem areas to explore, with safety incidents being one of the highest priorities. We started researching with the miners and together we uncovered fatigue as a recurring root cause in incidents. Working with the lead designer and safety specialists, I helped develop the ReadiWatch system—a wearable solution that reduced fatigue incidents at mines.

Problem & Opportunity

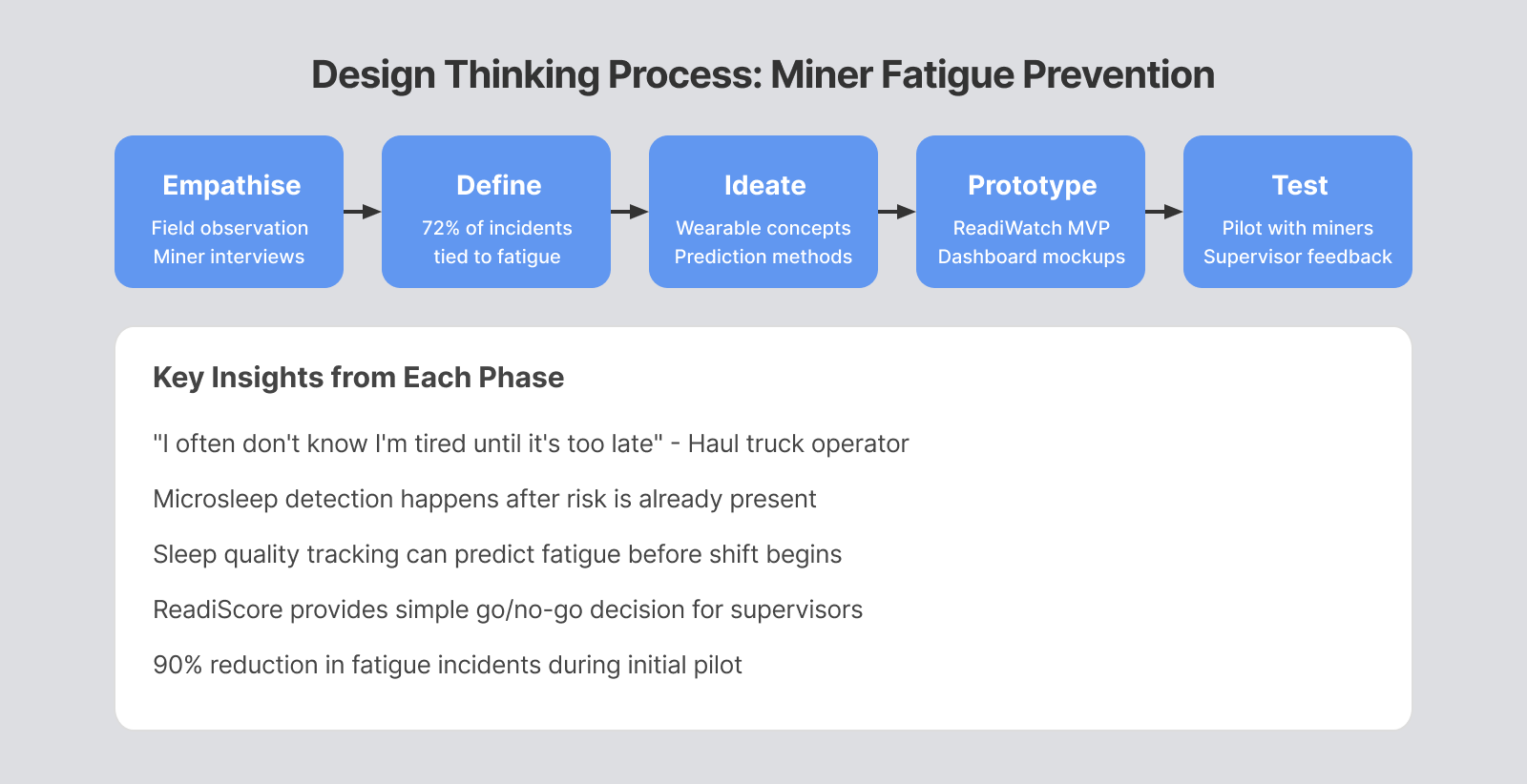

Through several interviews with the safety team, we began by analysing incident reports from the past two years to identify patterns. While reviewing these reports, we noticed fatigue appeared repeatedly as either a confirmed or suspected cause in many severe incidents. Despite existing several layers of checks and manual controls, there was no active way to ensure operators in high-risk roles were getting enough sleep between shifts. We interviewed and conducted diary studies with equipment operators, supervisors, and safety managers to better understand the problem. Through these explorations, a clear issue emerged: the existing Driver Safety System only detected microsleeps after they occurred—when it was already too late to prevent a potential accident.

Research findings

Working with the lead designer, we conducted field observations during shift changes and reviewed the existing fatigue management process. Our key findings included:

- Equipment operators often weren't aware of their own fatigue levels until experiencing a microsleep

- Supervisors had no visibility into sleep patterns before shifts began

- The mining environment required extremely durable technology

- Any solution would need to balance safety needs with operator privacy

A compelling insight was captured during operator interviews when it was reported that microsleeps are often detected by the system only after a truck could have already veered off course.

Ideation process

I helped faciliate in a cross-functional workshop with safety specialists, equipment operators, and supervisors to generate solutions. We started by mapping the operator journey from off-shift sleep to on-duty operation, identifying key intervention points. During the ideation phase, we came up with several concepts:

- A pre-shift eye-tracking test to measure fatigue

- A mobile app for self-reporting sleep quality

- A wearable sleep tracker with supervisor alerts

After evaluating options against feasibility, effectiveness, and operator acceptance criteria, the wearable concept emerged as the most promising solution.

Prototyping the solution

I worked closely with the lead designer to create prototypes of the physical wearable, the digital interfaces, and a test implementation process. We focused on understanding the ReadiWatch device implementation, monitoring operational processes, and identifying the steps needed for deploying the solution within Newcrest. From a design perspective, our goal was to create a system that would allow supervisors to quickly identify at-risk operators and take appropriate action before they began their shifts.

Final design & outcome

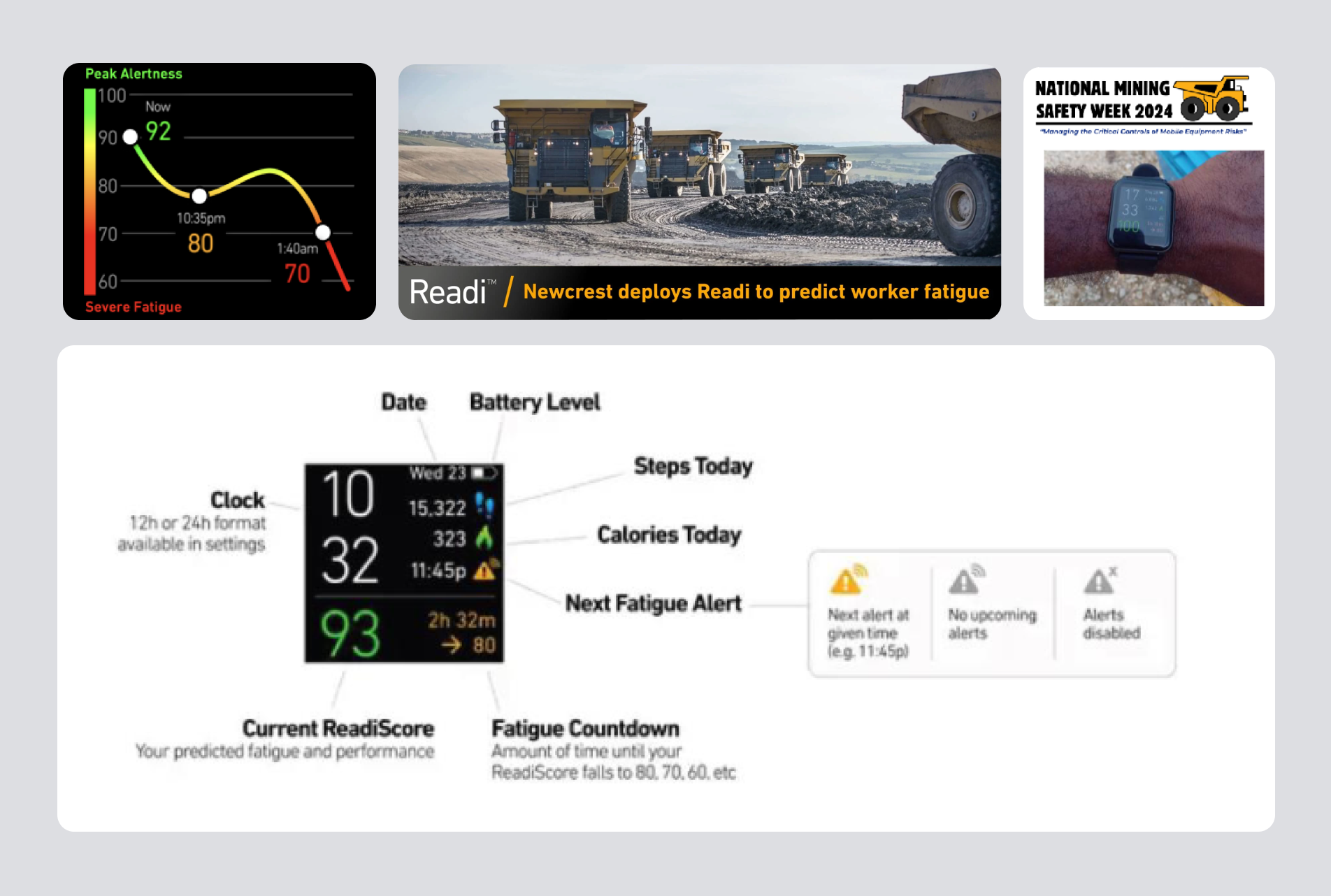

After rapidly testing and validating the value add of a wearable solution, ReadiWatch was chosen for its seamless integration into miners' routines and superior ability to predict fatigue risk before it impacted safety, rather than simply detecting incidents after they occurred.

- A rugged wearable device that miners would wear continuously to track sleep

- Sync stations positioned where operators gathered before shifts

- A supervisor dashboard highlighting operators with insufficient sleep

- Clear protocols for what actions to take when fatigue risk was detected

My role involved designing the dashboard interface that transformed complex sleep data into a simple ReadiScore that supervisors could easily interpret and act upon. Since implementation, the system has achieved a 90% reduction in fatigue events, shifting Newcrest's approach from responding to fatigue incidents to preventing them before they happened.

Lessons learned

This project taught me the value of thorough field research in understanding the true nature of a problem. By spending time with miners and observing their environment firsthand, we designed a solution that not only addressed the technical challenges but also fit naturally into their workflows. I also gained experience in:

- Designing for extreme environments where durability is essential

- Transforming complex data into simple, actionable insights

- Creating interfaces that support critical safety decisions

- Balancing automation with human judgment

Most importantly, I learned how design thinking can address serious safety issues and potentially save lives—giving real meaning to the work we do as designers.